Bedford College had issues with the cost and control of its heating and cooling systems – even after a major refurbishment of one of its buildings.

Their mechanical and electrical design consultant Panda CES approached Genius Hub to consider these concerns and offer some intelligent solutions.

THE SITUATION

Bedford College is the largest Further Education College in the South East Midlands, with multiple campuses catering for students and apprentices from age 16 onwards. In 2012, it retrofitted its Brundtland Building (named after a leading Norwegian environmentalist) as a showcase for applying alternative energy technologies and energy efficiency techniques in existing buildings. Despite new gas boilers and a building energy management system (BEMS), they still had some issues around heating

and cooling, along with high energy costs.

The building contains workshops, teaching rooms and administration offices and suffered from many of the problems found in similar buildings of this nature: Large workshops are used for bricklaying, carpentry and electrical installation training were particularly difficult to heat, and draughty windows caused further heat loss. Fan blowers were used, with the heat coming from the new gas boilers. These were noisy and inefficient and didn’t direct the heat to where it was needed as the warm air would quickly rise to the ceiling.

The classrooms had problems with over-heating on warm days and under-heating on cold days. Some of the classrooms and offices had split-system air-conditioning units. These were often running at the same time as the radiators and wasting a lot of energy.

Furthermore, as there was no timing control, the air conditioning units were also being left on overnight. If staff stayed late or classes were run in the evenings or weekends, the only option was to have the whole building on.

THE RIGHT KNOWHOW

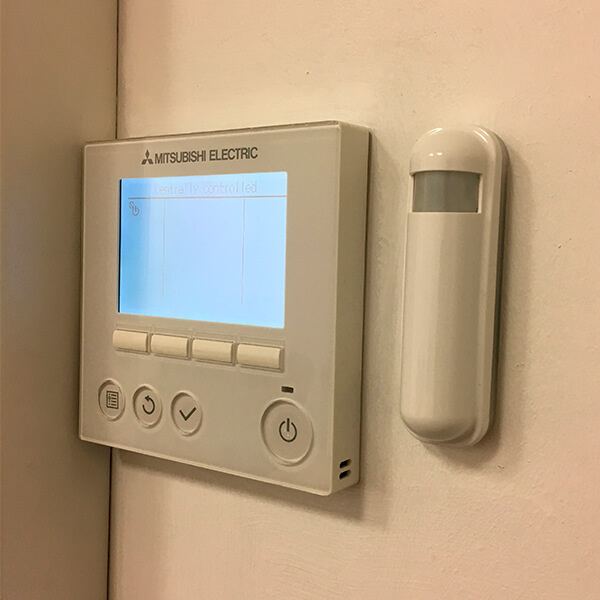

Intelligent, occupancy-based room sensors plus modern double panel radiators with smart TRVs (thermostatic radiator valves) have been added to each room. This allows pre-heating of the rooms before they are occupied and then keeps them at a pre-set temperature while being used.

As soon as a room becomes unoccupied, they automatically revert to a set-back temperature, saving energy and reducing costs. And if staff stay late or an event is running in the evenings or at weekends, only those rooms needed will be heated – not the entire building.

ll of the fan blowers for the workshops have been replaced with wet overhead radiant panels which radiate their heat downwards to the occupants in the room. These are also controlled on occupancy of the room. Existing air-conditioning units are now centrally controlled, so they cannot run at the same time as the heating or if there is no-one in the room.

THE ADVANTAGES

The installation of intelligent controls for the heating and cooling systems is expected to result in considerable cost-savings, as well as an enhanced learning and work environment within this showcase building. In this installation Bedford College chose Genius Hub as the controls supplier as all of the Genius Hub equipment is wireless, so with minimal disruption (as it is generally retrofitted to existing systems), installation normally takes just a few days and without impacting the normal operation of a building.

College staff and the maintenance team now take a hands-off approach to adjusting temperatures in the rooms, and any heating issues which arise can usually be dealt with through the Genius Hub app, which runs on a smartphone or computer web browser. The Genius Hub records all room occupancy and temperature data, giving admin staff valuable information on room usage levels. Exercising the pump and all the radiator valves regularly during the summer, to prevent seizing and sludge build-up, is now trivial and completed automatically. The Genius Hub system typically has a two to five-year payback period.